Die-Cast Zinc Alloy Guide: Benefits, Applications and Processing Tips

Core Keyword: die cast zinc alloy

Die-cast zinc alloy: a cost-effective material for precision manufacturing

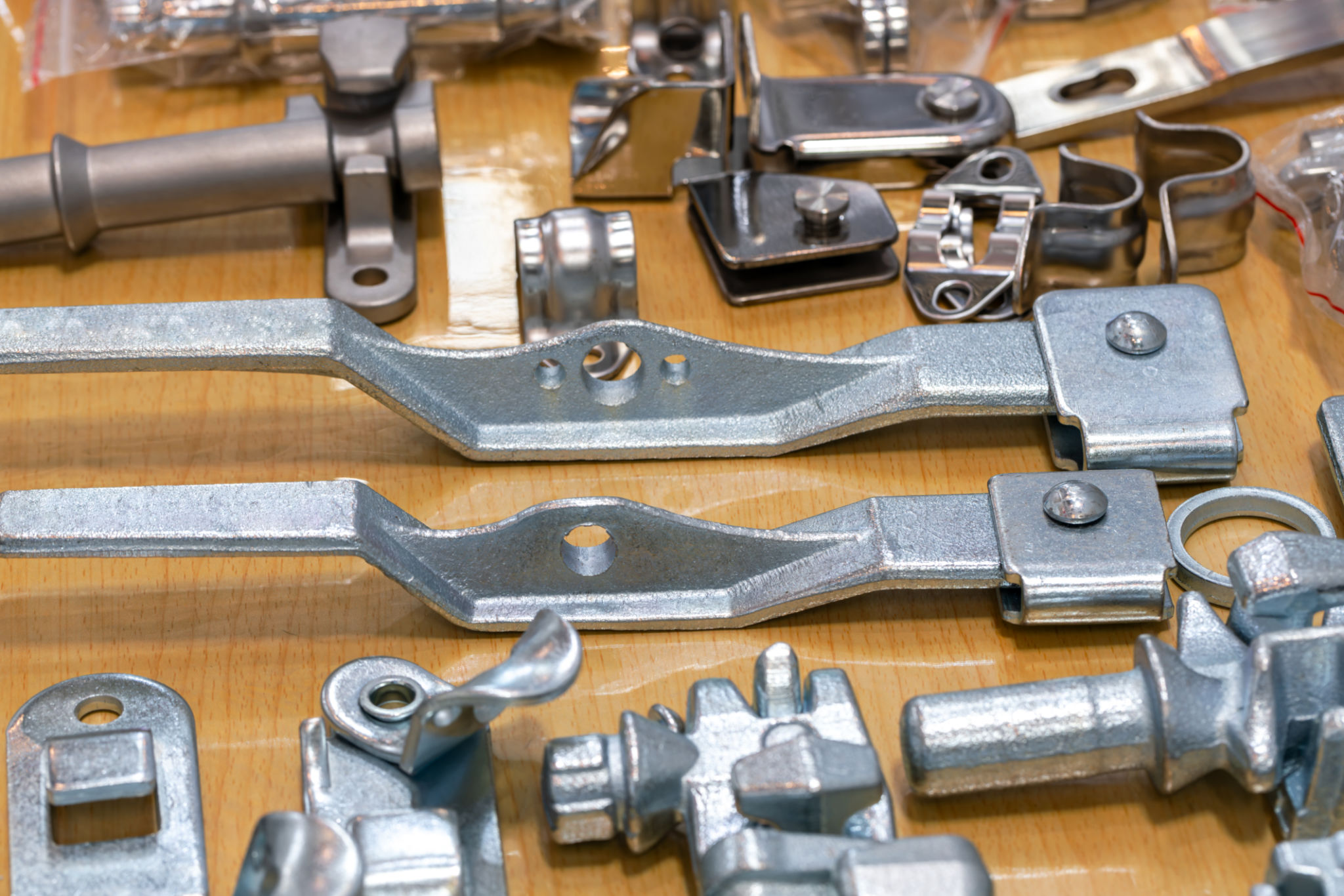

In the field of modern precision manufacturing, die-cast zinc alloy is widely used in electronics, automobiles, home appliances, hardware accessories and other industries due to its excellent forming performance, low melting point and cost advantages. Compared with materials such as aluminum alloy and magnesium alloy, zinc alloy performs better in the production of complex structures, thin-walled parts and high-precision parts.

According to Grand View Research, the global market for zinc alloy die casting surpassed USD 16 billion in 2024 and is forecast to exceed USD 23 billion by 2029, with a consistent annual growth rate of over 6.3%.In particular, zinc alloy die-casting continues to be favored due to its high cost-effectiveness and design flexibility in the fields of consumer electronics, lightweight automobiles and precision hardware manufacturing.

I. Zinc alloy material characteristics

Zinc alloy has the following significant characteristics:

-Excellent flow characteristics make it ideal for producing intricate and finely detailed components.

-Low melting point (about 380°C): reduces mold loss and energy consumption, and extends mold life.

-Excellent dimensional stability ensures minimal shrinkage and high precision in final parts.

-Good electroplating and surface treatment performance: suitable for various surface decoration needs.

-High recyclability: support the concept of green manufacturing.

II. Typical application scenarios of die-cast zinc alloy

1. Electronic and communication parts such as plug housings, radiators, shielding covers, etc.

2. Automotive structural parts and interior parts, such as door handles, decorative strips, accelerator pedal brackets, etc.

3. Consumer product shells: such as locks, handles, small appliance parts, etc.

4. High-end customized accessories: Due to its good processability, it is also suitable for exquisite gifts, customized hardware, etc.

III. Precautions for zinc alloy die-casting processing

Key considerations during the zinc alloy die-casting process include:

-Maintaining optimal mold temperatures minimizes the risk of casting flaws such as incomplete fills and internal voids.

-Alloy composition control: The commonly used Zamak series (Zamak 3, Zamak 5) need to be accurately proportioned to ensure mechanical properties.

-Surface treatment matching: Such as spraying, electroplating, anodizing, etc., the treatment process needs to be customized according to the purpose.

Conclusion

On the whole, die-cast zinc alloy is a preferred material for both performance and cost, suitable for mass production of small and medium-sized complex structural parts. Its good processing performance and plasticity appearance make it irreplaceable in the current diversified manufacturing needs. If you need to develop a zinc alloy die casting project, please contact an experienced zinc alloy die casting manufacturer to get a one-stop OEM solution.

If you are looking for a trusted zinc alloy die casting supplier, we can provide you with one-stop services from mold development, die casting production to surface treatment. Whether it is complex structural parts or precision decorative parts, SHD Precision Diecasting can customize high-quality zinc alloy die casting solutions according to your drawings and requirements.

📩 Welcome to contact us for free proofing suggestions or quotation solutions.