Green and Smart Die Casting: Driving the Future of Sustainable Manufacturing

The global die casting industry is entering a transformative era where digital intelligence and environmental responsibility are no longer optional—they're essential. As pressure mounts to increase efficiency and reduce environmental impact, manufacturers worldwide are turning to smart die casting and green die casting practices to meet both industrial and regulatory demands.

The Rise of Smart Die Casting Technologies

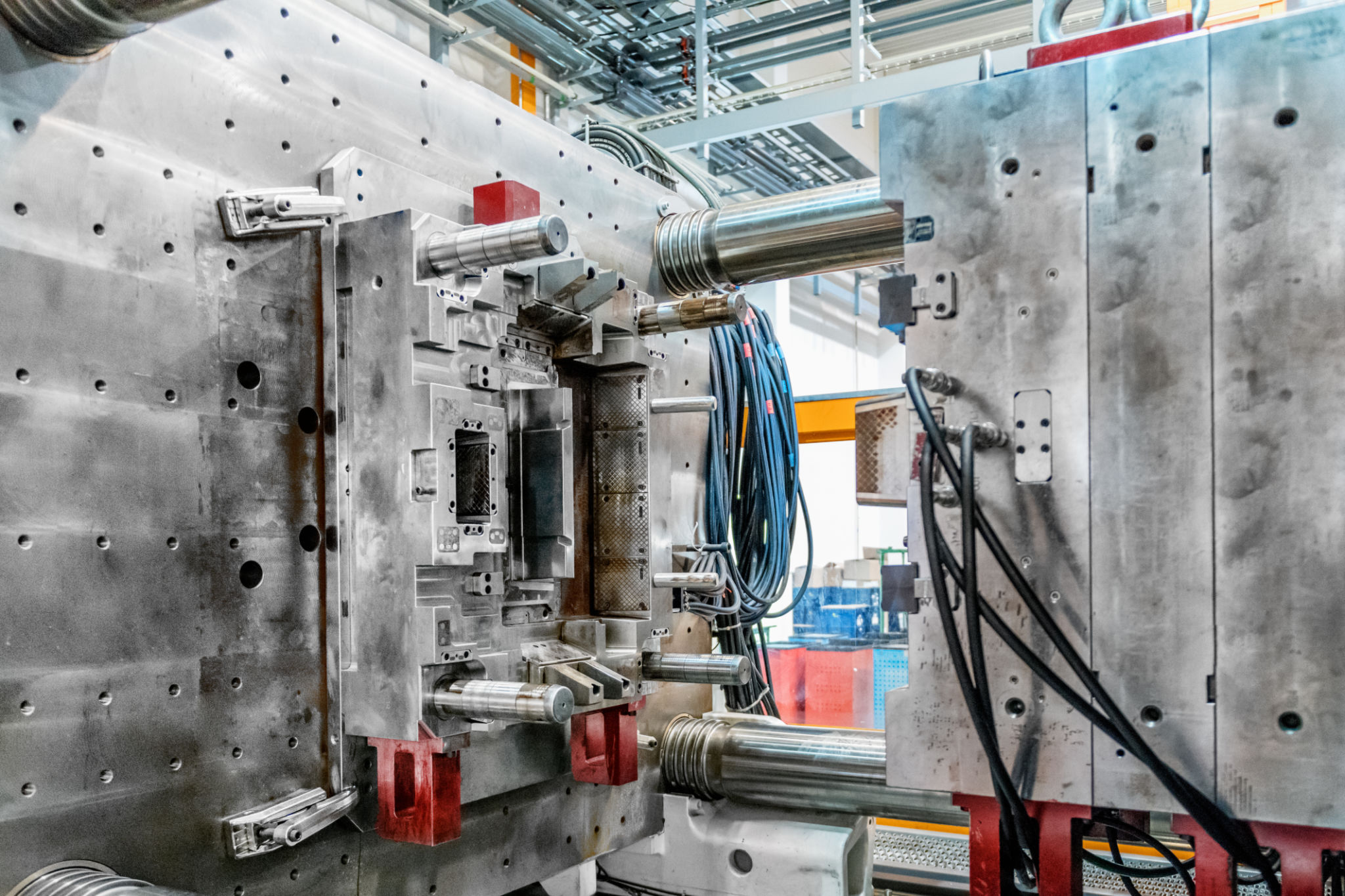

The implementation of smart die casting systems enables manufacturers to monitor, control, and optimize every aspect of the production cycle in real time. IoT sensors, AI-driven analytics, and predictive maintenance are becoming standard in advanced foundries, forming the foundation of what is now referred to as a smart die casting factory.

According to a 2024 report by Casting Source Magazine, over 60% of die casting facilities in North America have implemented at least one smart manufacturing module, with predictive maintenance alone reducing unplanned downtime by up to 30%.

Real-time monitoring of injection pressure, die temperature, and cycle time allows manufacturers to detect process deviations early and avoid costly defects. For example, systems like Bühler's SmartCMS and Italpresse Gauss's Monitizer enable remote visualization and AI-guided optimization of casting cells—minimizing human error and improving repeatability in smart die casting environments.

Digital twin technology, which creates a real-time virtual replica of the die casting process, enables engineers to test and fine-tune process parameters before launching full-scale production. By simulating metal flow, thermal conditions, and cycle timing in advance, manufacturers can significantly reduce development lead time, material waste, and trial costs. These innovations are central to smart die casting operations, contributing to improved dimensional accuracy, faster optimization cycles, and more reliable outputs.

Green Die Casting: Sustainability in Action

Green die casting focuses on reducing the environmental footprint of metal manufacturing through energy efficiency, resource recycling, and cleaner production techniques.

A standout example is aluminium recycling. The Aluminum Association reports that recycled aluminium uses 95% less energy than primary aluminium, cutting greenhouse gas emissions by up to 92%. Similarly, recycled zinc alloys like Zamak maintain their mechanical properties while reducing the need for primary resource extraction—making them ideal materials in green die casting applications.

At the same time, major OEMs are increasingly requiring their suppliers to provide evidence of sustainable operations, such as reduced carbon emissions, energy-efficient equipment, and closed-loop resource systems. This growing pressure is accelerating the adoption of green die casting practices across the supply chain. In response, die casting foundries are investing in:

-Closed-loop cooling systems, reducing water usage by up to 80%

-Electric melting furnaces, powered by renewable energy

-Scrap recycling and re-alloying, cutting raw material waste by 30–40%

-Energy management software, used to identify inefficiencies in real time

According to industry analyst David P. Smith from FoundryWorld:

“The future of die casting isn’t just about precision—it’s about precision with purpose. Sustainability and smart control are no longer advantages; they’re expectations.”

SHD Precision Diecasting: Smart, Green, and Ready for the Future

At SHD Precision Diecasting, we are committed to leading the industry into a new era of smart die casting. Our production lines are equipped with IoT-driven monitoring systems, CNC-controlled injection, and digital quality assurance to ensure each component meets strict dimensional and performance standards. These technologies allow us to optimise casting parameters in real time, reduce downtime, and deliver greater process transparency to our clients.

Equally, we take pride in our adoption of green die casting principles. We use high-efficiency electric furnaces, closed-loop cooling, and recycled aluminium and zinc alloys to significantly reduce our environmental footprint. By combining advanced automation with sustainable practices, SHD offers solutions that align with the growing demand for carbon-conscious and cost-effective manufacturing.

Whether you're developing high-precision components for automotive, electronics, or industrial systems, SHD Precision Diecasting delivers reliable, scalable, and environmentally responsible results. Partner with us for smart and green die casting solutions that meet today’s technical standards—and tomorrow’s sustainability expectations.