Future of Die Casting: Top Components with High Growth Potential by 2035

Core Keywords: future of die casting, die cast parts

In a rapidly evolving global market, die cast parts are undergoing a transformation. Driven by electric vehicles, renewable energy, and miniaturized electronics, new demands are reshaping the future of die casting. From lightweight EV structures to precision components in 5G and LED technology, manufacturers are entering a new growth era. This article explores which die cast components are set to lead the industry between 2025 and 2035.

The Future of Die Casting: Which Components Will Dominate the Next Decade?

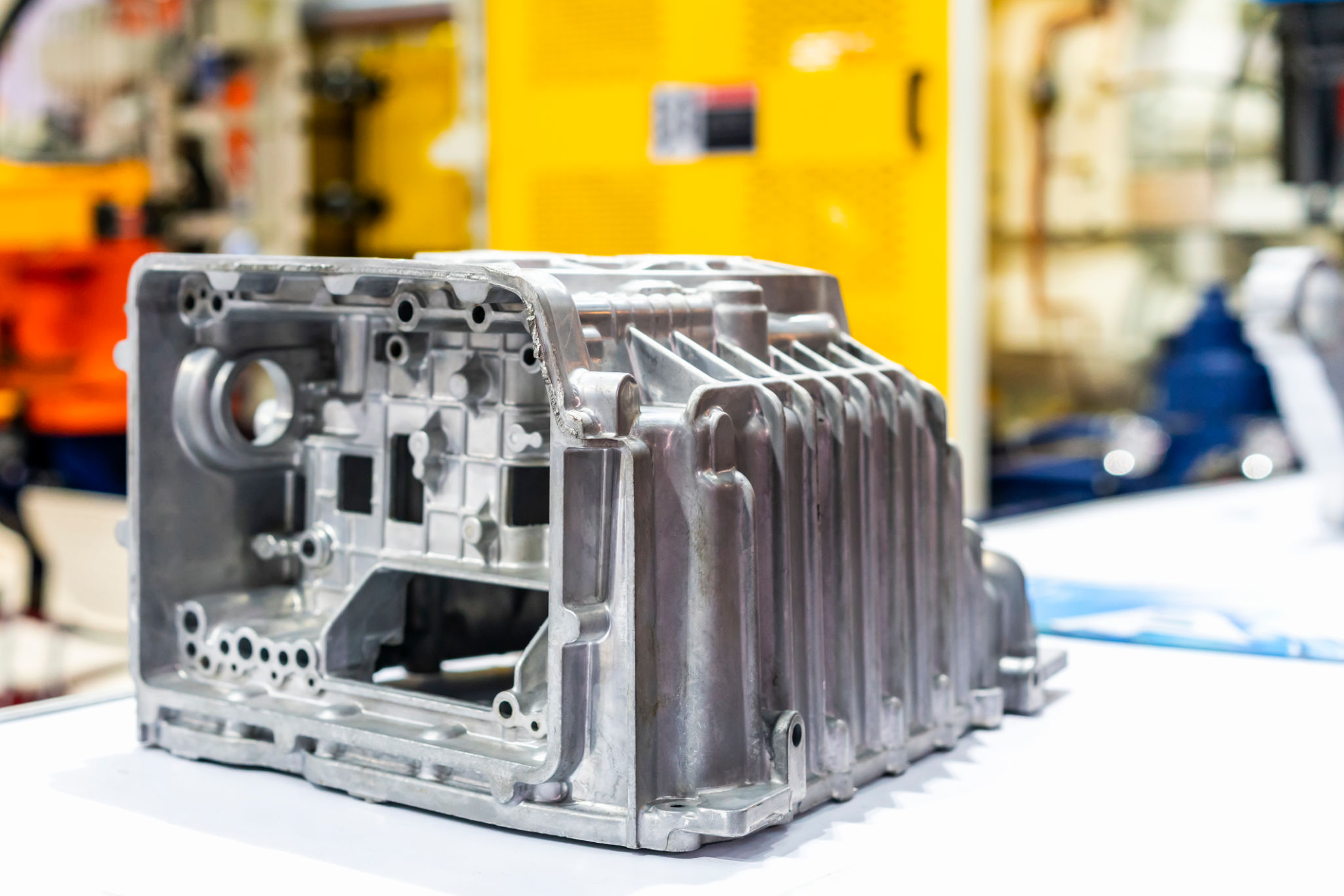

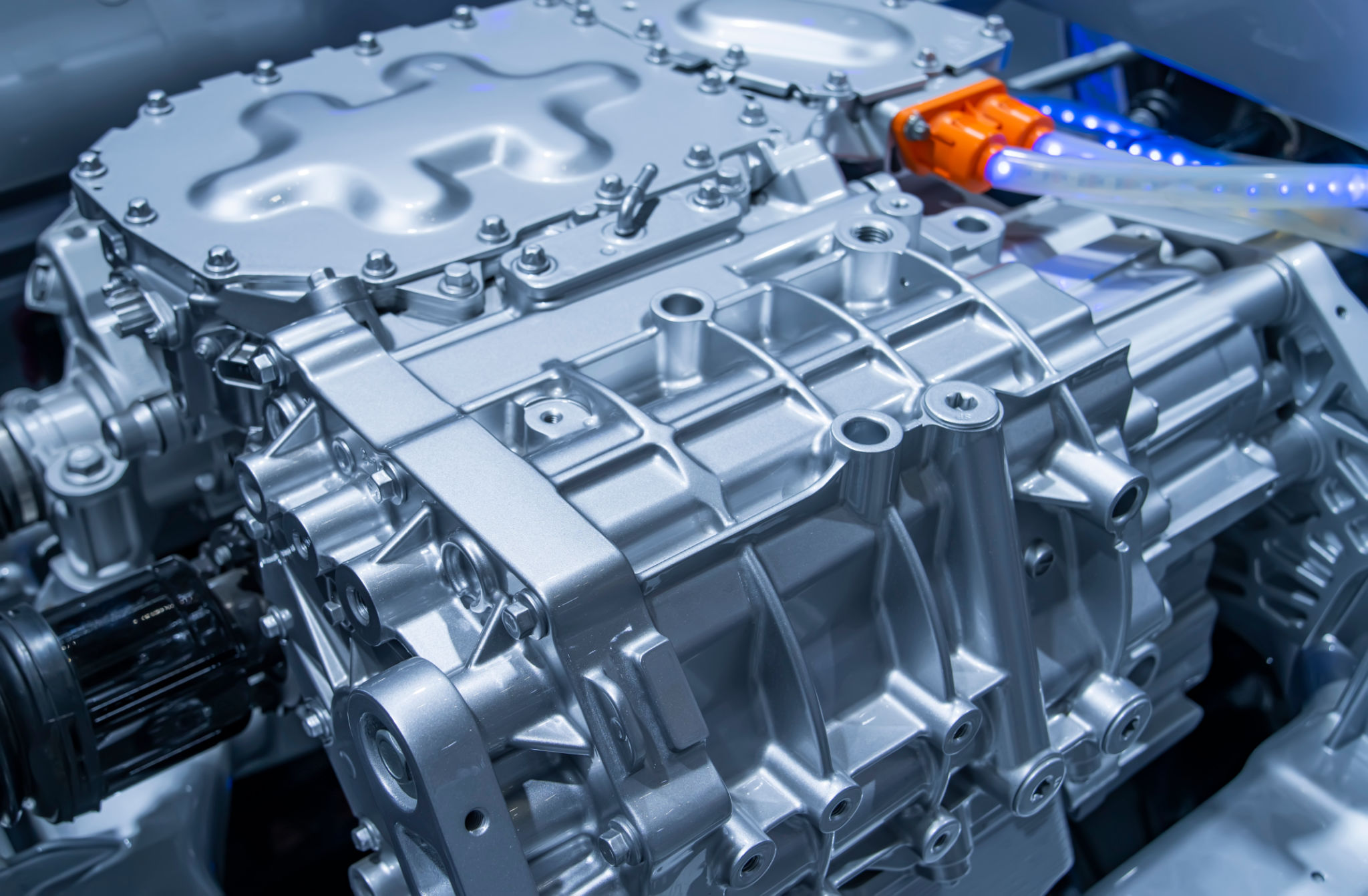

1. EV Components: The Largest Growth Driver

The electric vehicle (EV) boom is the most significant force behind high-growth die casting components. Aluminum die cast parts are widely used for EV motor housings, battery enclosures, inverter casings, and lightweight structural parts. These applications require a combination of strength, thermal conductivity, and complex geometries—all achievable with high-pressure die casting.

According to Allied Market Research, the global EV die casting market is expected to exceed $45 billion by 2030. As automakers push for vehicle light-weighting and modular integration, large structural castings (like Tesla’s Giga Casting) are becoming the new standard. This signals a pivotal chapter in the future of die casting.

2. 5G & Telecommunications Equipment Housings

Miniaturized, high-precision die cast parts are essential in 5G and next-gen telecom systems. From antenna housings to connector shells and signal modules, zinc and magnesium alloys are favored for their excellent dimensional control and EMI shielding capabilities.

These components demand precise die casting applications due to their thin walls, intricate cavities, and surface quality requirements. As global 5G infrastructure expands, especially in Asia and North America, the demand for telecom-related castings will surge.

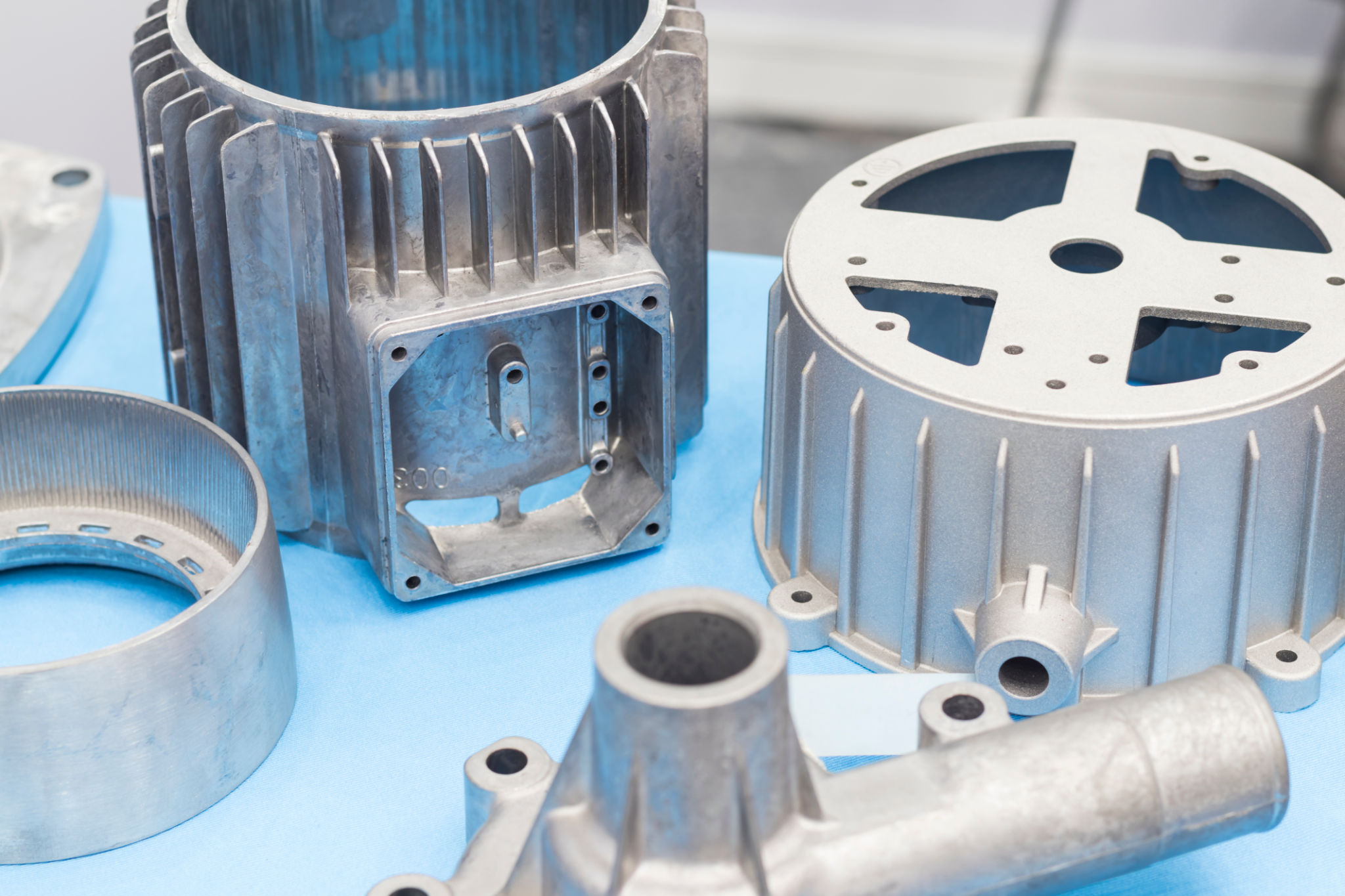

3. LED Heat Dissipation Frames & Optical Components

The lighting sector is increasingly adopting die casting solutions, especially for thermal and structural efficiency. With the rise of Mini LED and Micro LED, aluminum die cast frames for heat dissipation are increasingly used in TVs, automotive lighting, and smart streetlamps.

High thermal conductivity, design flexibility, and low unit costs make aluminum a superior choice for LED component housings. The move towards smart lighting and automotive LED clusters will further accelerate this demand and shape the future of die casting in electronics.

4. Consumer Electronics & Wearable Device Housings

Wearables and mobile accessories are leaning into magnesium and zinc alloy die casting to achieve compact, robust, and lightweight device shells. Smartwatches, TWS earbuds, and portable chargers benefit from die casting's ability to deliver high strength in tight spaces.

This trend marks a shift from CNC machining of solid billets to more cost-effective precision die cast parts, especially for mass production runs.

5. New Energy & Battery Storage Enclosures

Driven by surging investment in renewable energy, die cast aluminum enclosures are emerging as a preferred choice for modern energy storage systems. Compared to conventional sheet metal or welded steel housings, these cast solutions deliver superior thermal conductivity, enhanced mechanical strength, and robust IP-rated sealing performance.

As grid-scale and residential battery adoption increases, particularly in Europe and the U.S., this segment will see strong upward momentum in the future of die casting.

6. Future Watchlist: Hydrogen Systems & Drone Frames

Emerging technologies are giving rise to novel die casting opportunities:

Hydrogen fuel cells require pressure-tight, lightweight enclosures—a potential niche for aluminum die casting.

Consumer and industrial drones are exploring cast magnesium frames for weight reduction without compromising durability.

Conclusion

The next decade of die casting will be shaped by three principles: integration, precision, and sustainability. As global industries shift toward electrification and lightweighting, demand for innovative die cast parts will rise across sectors. These shifts underscore how innovation and manufacturing agility are shaping the next chapter in the future of die casting.

If you're exploring OEM partnerships or need expert support in high-growth die casting components, SHD Precision Diecasting is here to help—specializing in aluminum, zinc, and magnesium alloys with CNC finishing capabilities.